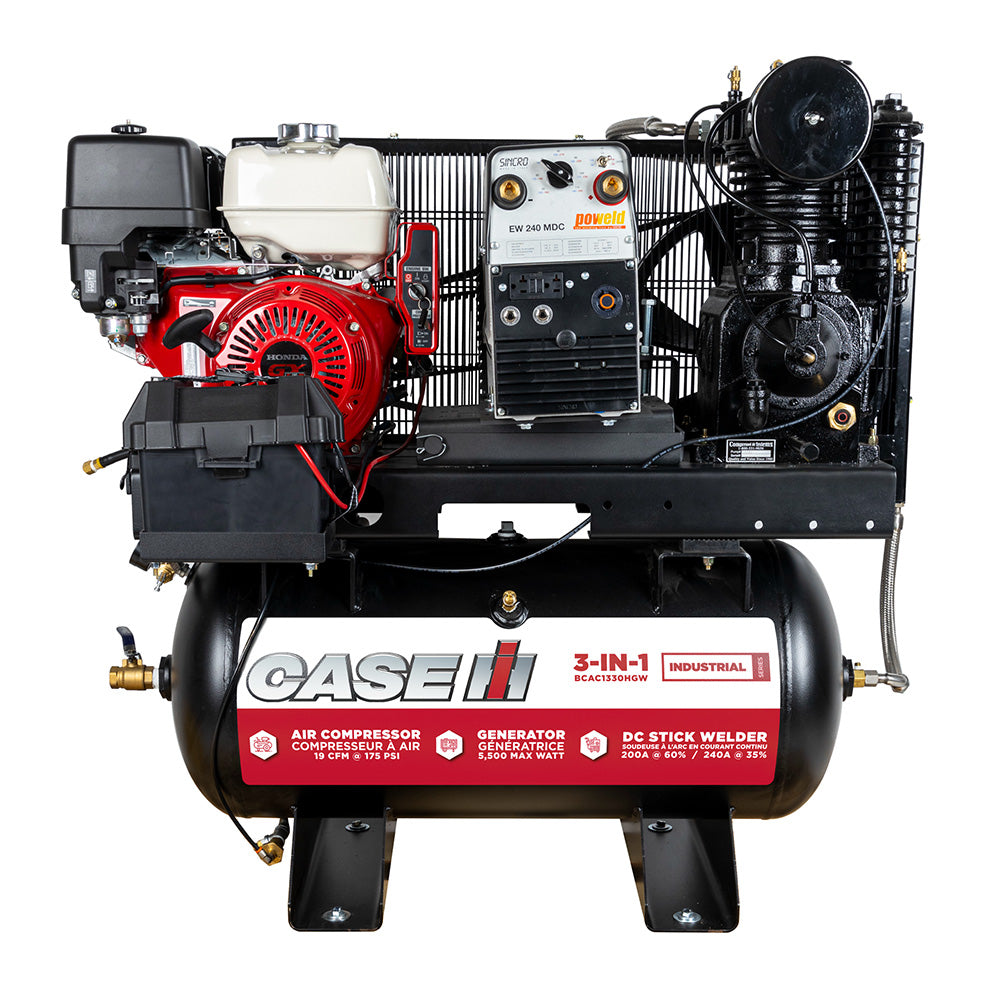

Case IH 175 PSI 19 CFM Truck Mount Air Compressor and Welder

Specifications

CFM RATING

19 CFM @ 175 PSI

DIMENSIONS

43″x31″x44″

ENGINE

Honda GX390

ENGINE FUEL TANK CAPACITY

6.1L (1.6G)

PUMP OIL TYPE

30w Non-Detergent

PUMP UNLOADING SYSTEM

Centrifugal

MAX PSI

175

PUMP TYPE

Two-Stage Heavy Cast Iron

TANK SIZE

30 Gallons

WARRANTY

3 Year

WEIGHT

585 lbs

Integrated Power for Professional Welding and Compressed Air Applications

Powered by the legendary Honda GX390 engine, this system delivers 19 CFM at 175 PSI of compressed air, up to 5,500 watts of generator power, and a DC stick welding output of up to 250 amps. Designed for mobile service trucks, construction sites, and remote operations, it provides dependable power and performance in a compact, durable package.

Key Features

-

Air Compressor Output: 19 CFM @ 175 PSI

-

Maximum Pressure: 175 PSI

-

Tank Capacity: 30 gallons – for sustained air delivery

-

Engine: Honda GX390 – commercial-grade reliability

-

Start Type: Recoil and electric start with battery for flexibility

-

Engine Oil: 10W30 recommended for optimal lubrication

-

Fuel Tank Capacity: 6.1 liters (1.6 gallons) for extended run time

-

Pump Type: Two-stage, heavy cast iron for durability and performance

-

Pump Oil: 30W non-detergent for clean, effective lubrication

-

Pump Unloading System: Centrifugal for automatic pressure control

-

Generator Output: 5,500 max watts, 5,000 running watts

-

Welder Process: DC Stick (SMAW) – versatile and reliable

-

Welder Amp Range: 180–250A for heavy-duty welding applications

-

Welder Voltage: 120–180 DC

-

Welder Duty Cycle: 60% at 200A – for sustained, professional welding

-

Electronic Engine Display: Provides real-time monitoring of battery volts, coolant temperature, fuel level, and oil pressure, displays engine diagnostics, and tracks oil change intervals for easy maintenance and troubleshooting.

-

Dimensions: 43″ x 31″ x 44″ – compact footprint for service vehicles

-

Weight: 585 lbs – rugged and stable

-

Warranty: 3 years on Honda engine

Air Compressor – Industrial-Grade Power and Performance

The integrated air compressor delivers 19 CFM at 175 PSI, making it ideal for powering a wide range of pneumatic tools including:

-

Impact wrenches

-

Air hammers

-

Grinders and sanders

-

Tire inflation equipment

-

Spray guns

The two-stage heavy-duty cast iron pump ensures long-lasting durability, efficient air compression, and reduced wear even under continuous use. Designed for high-pressure applications, the 30-gallon air tank provides ample storage to minimize compressor cycling and maintain consistent airflow.

The centrifugal unloading system automatically manages pressure levels, improving pump longevity by reducing unnecessary load during startup and shutdown cycles.

Honda GX390 Engine – Proven Reliability

At the heart of this system is the Honda GX390 engine, one of the most trusted engines in the outdoor power equipment industry. Known for easy starts, exceptional fuel efficiency, and long service life, the GX390 provides consistent power to run the air compressor, generator, and welder simultaneously.

Key engine features include:

-

Dual starting system: electric start with battery for convenience, plus recoil start for backup

-

OHV design for cooler, more efficient operation

-

3.6 kW output capable of driving all integrated functions

-

Low oil shutdown for automatic engine protection

-

6.1-liter fuel tank for extended runtime with fewer fuel stops

The Honda GX390 is backed by a 3-year commercial warranty, ensuring years of reliable service.

DC Stick Welder – Versatile Field Welding Solution

This unit integrates a professional-grade DC stick welder (SMAW) with an amp range of 180 to 250 amps, making it capable of tackling a wide range of welding applications:

-

Equipment repair

-

Structural welding

-

Pipe welding

-

Heavy-duty fabrication

-

Field repairs on construction machinery and vehicles

The 120–180 volts of DC power ensures smooth, stable arcs with excellent penetration and minimal spatter, ideal for welding in various conditions.

With a 60% duty cycle at 200A, this welder is built for sustained, heavy-duty operation, allowing professionals to complete larger welding tasks without frequent cooldown periods.

In traditional systems, conventional dig delivers a preset amount of short clearing current to clear a short circuit, which is fixed and does not adapt to changing conditions. In contrast, advanced dynamic dig technology uses a time based algorithm that automatically adjusts the current required for short clearing. This allows the welder to match application, material, fit up, and welder technique, resulting in a smoother, more consistent arc across a variety of welding scenarios.

High-Capacity Generator – Reliable Jobsite Power

The integrated generator provides up to 5,500 max watts and 5,000 running watts, sufficient to power:

-

Corded power tools

-

Battery chargers

-

Lighting equipment

-

Jobsite electronics

With this level of output, the unit can simultaneously run pneumatic tools, welding operations, and electric equipment, making it a true all-in-one jobsite powerhouse.

The single integrated system saves valuable space on service trucks and trailers and eliminates the need to transport multiple separate machines.

Rugged Design and User-Friendly Features

Built to endure the rigors of field work, the Case IH Air Compressor and Welder features:

-

Heavy-duty frame to withstand impacts and rough handling

-

Compact footprint for efficient installation on service vehicles, trailers, or workshops

-

Accessible controls conveniently located for easy operation directly at the operator's fingertips for compressor, welder, and generator functions

-

Integrated control panel for monitoring system status, voltage, and pressure

-

Stable base to minimize vibration during operation

The design also allows for quick and easy servicing, minimizing downtime for routine maintenance and engine checks.

Accessories and Interfaces

To maximize the performance and convenience of engine driven welders, a range of advanced accessories and interfaces are available. The ArcReach system stands out as a must-have for professionals, enabling users to change weld settings and control the machine remotely from their work area. This full remote control capability means less time walking back and forth, and more time focused on welding.

For those working with aluminum or in demanding industrial environments, the ArcReach Smart Feeder system delivers exceptional results, especially when paired with a compatible power source like the Dimension, XMT, or an engine-driven ArcReach unit. This system ensures precise control and a consistent arc, even in challenging applications.

Maintaining clean, dry air is essential for air tools and pneumatic systems. A regenerating inline air dryer system eliminates moisture from the air stream, preventing tool freeze-ups in cold climates and ensuring reliable operation. Protective covers, specifically designed for models like the Big Blue 600 Air Pak/800 Series with Deutz, safeguard your investment from the elements and jobsite hazards.

Modern engine driven welders also feature user-friendly interfaces such as industrial USB ports. These allow operators to download machine log files, retrieve in-depth information, and update to the latest software, making machine management and maintenance more efficient. The ability to track oil change intervals, engine hours, and machine statistics, as well as display engine diagnostics, helps prevent overheating and ensures your system remains in peak condition.

With these accessories and interfaces, you can keep your engine driven welder, air compressor, and power tools running smoothly, while maintaining full control and easy servicing on any jobsite.

Comparison to Other Brands

When comparing the New Holland 19 CFM @ 175 PSI Air Compressor and Welder to other leading brands, the Miller Big Blue 600 Air Pak truck mount spec is often cited as a benchmark for power and versatility. The Big Blue 600 Air Pak is renowned for its dual-operator productivity, multiprocess flexibility, and air-purified welding system, making it a favorite among professionals tackling heavy-duty applications.

One of the standout advantages of the Big Blue 600 Air Pak is its greater fuel savings, thanks to advanced engine technology and the greenest diesel power option featuring a diesel oxidation catalyst. This not only reduces emissions but also extends the time between refueling, making it an environmentally friendly and cost-effective choice.

In terms of performance, the Big Blue 600 Air Pak delivers a smoother, more consistent arc and longer compressor service intervals, reducing downtime and maintenance costs. Its ability to communicate process adjustment commands and track machine statistics allows for precise control and easier management, ensuring optimal results on every job.

While other brands may offer similar features, the unique combination of power, flexibility, and user-friendly design found in the Big Blue 600 Air Pak sets it apart. For professionals who demand reliable air, power, and welding capabilities from a single truck-mounted system, both the New Holland and Big Blue options deliver, but the Big Blue’s advanced technology and serviceability make it a top contender in the industry.

Truck Mount Options

For professionals who require maximum mobility and efficiency, truck mount options like the Big Blue 600 Air Pak are designed to meet the demands of heavy-duty jobsites. These systems can be securely mounted on the bed of a large-body truck, providing easy access to critical controls and ensuring your air compressor, welder, and power source are always within reach.

The truck mount configuration is ideal for dual-operator applications, especially on labor-intensive jobsites or in environments where space is at a premium. With the ability to wire the unit for 120 or 240 VAC loads and connect to various input voltages using Auto-Line technology and MVP Adapters, integration with existing equipment is quick and straightforward.

Despite its robust capabilities, the compact unit weighs just 51 lbs, yet delivers ample power for tasks like 7/8 in. mild steel cutting, making it a versatile solution for a wide range of applications. Security is also a priority, with lockable hinged steel panels that protect the name plate, gauges, and ignition switch from theft or damage.

Whether you’re outfitting a service truck for construction, industrial maintenance, or emergency repairs, truck mount options like the Big Blue 600 Air Pak provide the technology, power, and space-saving design needed to keep your equipment and crew operating at peak performance.

Engine driven welders are a cornerstone of mobile welding and power generation, combining a robust engine—powered by gasoline, diesel, or propane—with an integrated generator to deliver reliable energy for a variety of welding processes, including Stick, TIG, MIG, and Flux-Cored welding. These versatile machines are designed for mobility, typically mounted on a truck or trailer, making them ideal for outdoor and remote jobsites where access to grid power is limited or unavailable.

By serving as both a welder and a stand-alone generator, engine driven welders save valuable space and money, eliminating the need for multiple pieces of equipment. They can also power additional tools such as air compressors, hydraulic pumps, and battery jump-start terminals, further enhancing their utility on the jobsite.

Selecting the right engine driven welder is crucial for matching the demands of your specific job. Factors like compressor duty cycle, air compressor requirements, and welder generator capabilities must be carefully considered to avoid undersizing or oversizing your equipment. The latest technology in engine driven welders includes wireless interface control, allowing operators to communicate process adjustment commands from a distance. This not only streamlines workflow but also results in a smoother, more consistent arc, improving weld quality and operator efficiency.

Whether you’re running a stick welding process, powering air tools, or managing multiple tasks from your truck, today’s engine driven welders offer the control, technology, and space-saving design to keep your operation running smoothly.

Warranty and Support

Case IH backs this system with a 2-year warranty on the pump and a 3-year warranty on the Honda engine, ensuring that your investment is protected against defects and offering peace of mind for years of reliable operation.

The Case IH 19 CFM @ 175 PSI Air Compressor and Welder is the ultimate combination unit for professionals who need compressed air, electrical power, and welding capability all in one reliable package.

Whether you’re servicing equipment in the field, running a construction crew, or managing emergency repairs, this machine delivers the performance, versatility, and durability you need to keep the job moving.

Power your tools. Weld with confidence. Move air efficiently. Do it all with Case IH.